Marshalling Internal Wiring 24 v DC Bas Bar Aayansh

In this video, I explained about the marshalling cabinet, types, components, equipment and devices inside the DCS marshalling panel.Marshalling cabinet in a.

What is Marshalling ? InstrumentationTools

In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments. It achieves this using the marshalling technique that.

What is a Marshalling Design, Types, Advantages

Traditionally marshalling may involve up to five separate cabinets, one for each of the different marshalling functions, with complex wiring between the marshalling components. Interconnection is a key concern. Historically, marshalling solutions require up to eight interconnections per channel. However, this creates a complex wiring structure.

Oil and Gas Engineering Marshalling or Marshalling Panel

Electronic Marshalling Overview - EmersonLearn how Electronic Marshalling simplifies the design, installation and maintenance of process control systems by eliminating the need for conventional marshalling cabinets and reducing wiring costs. This document provides an overview of the Electronic Marshalling concept, components, benefits and applications.

What is Marshalling ? InstrumentationTools

A marshalling cabinet is a type of electrical enclosure that is used to organize and terminate field wiring in an industrial process control system. A marshalling cabinet is typically used in systems that have a large number of input and output (I/O) points, such as programmable logic controllers (PLC) and distributed control systems ( DCS ).

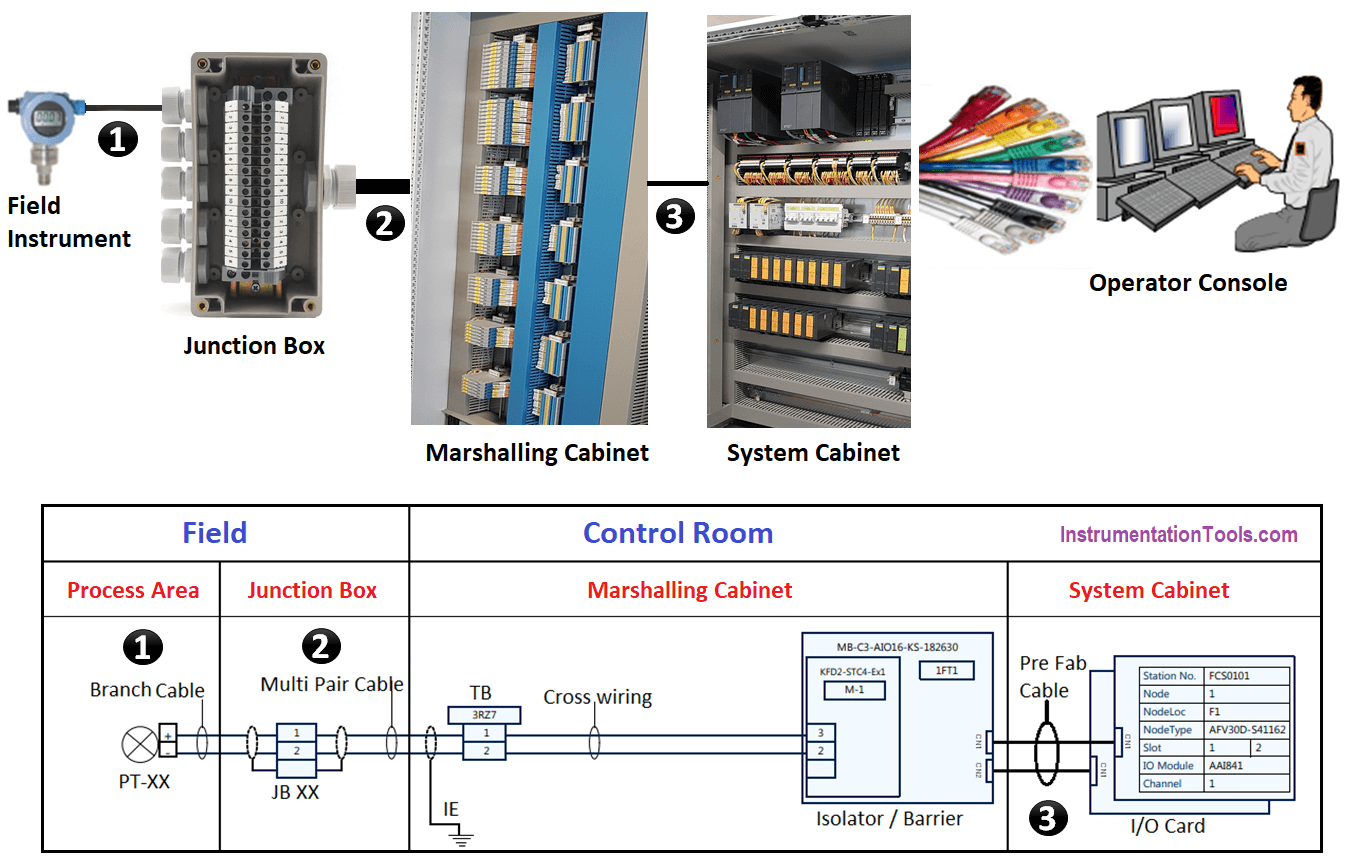

PLC Connection Instrument, Junction Box, Marshalling & System

In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments. It achieves this using the marshalling technique that involves the grouping of I/O (Inputs/Outputs), which makes them easy to identify.

Honeywell DCS TDC 3000 Marshalling and FTA Wiring

Marshalling cabinet main purpose is to provide main cables termination and then re-distribute the field devices to respective Analog Input/Output card using internal wiring. Internal wiring will be used to connect from Marshalling cabinet to system cabinet. Wiring between Marshalling and System Cabinets

DCS System Layout and its Different Parts Instrumentation Tools

DeltaV Distributed Control System (DCS) DeltaV Controllers and I/O DeltaV Electronic Marshalling with CHARMs Remove The Complexity of Marshalling Field Wires DeltaV S-series Electronic Marshalling with CHARMs lets you land field cabling wherever you want, regardless of signal type or control strategy.

Foundation Fieldbus Installation and Best Practices

This demonstration shows how DeltaV S-series electronic marshalling dramatically reduces installation and maintenance costs while increasing engineering and.

View Marshalling Panel Wiring Diagram Images Wiring Consultants

universal marshalling solution provides the flexibility to connect to two-wire devices, three- wire devices, relays, thermocouples, RTDs, etc. without any custom wiring or cabinet redesign. As shown in Figure 3, field wiring is handled in a clean way in the cabinet with ample space for maintenance. The solution also provides the

First time terminating a marshalling with bypass key switches

Reduces installed cost of system: DeltaV Electronic Marshalling helps reduce overall system cost by eliminating internal cabinet cross wiring, reducing overall footprint, simplifying I/O channel assignments, and reducing FAT activities.

Marshalling Box Wiring Diagram Bestn

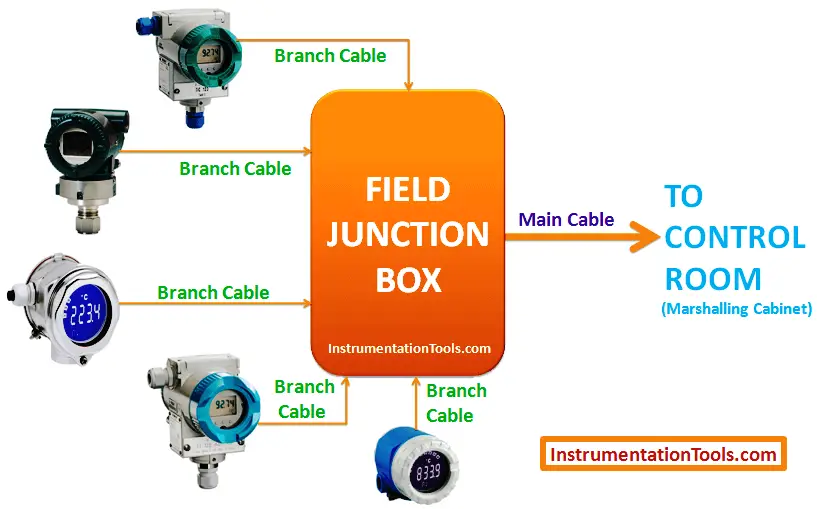

The termination assemblies are connected via prefabricated cables to input/output modules in system cabinets. In simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules.

Marshaling And Panel at Best Price in Navi Mumbai Expert

The loop diagram shows the instrument (in a symbol) and its terminal numbers that need to be connected, the cable number, the junction box number, the terminal number assigned to the specified instrument, the multipair cable and pair number, the marshalling cabinet number, the terminal number in the marshalling cabinet, and the control system de.

Marshalling Panel Wiring Diagram

The marshalling cabinet serves as the primary termination point for incoming field cables. The incoming field wire is generally a multipair cable. After getting terminated in the marshalling cabinet, the other ends of wires are connected to the system cabinet internally where the I/O cards and controller are installed.

Marshalling wiring कैसे करते है Instrument Guru YouTube

Three common methodologies for marshalling are half-knit, fan-out, and cross-wire. Half-knit Half-knit marshalling performs the scrambling on the system side. The field cables are terminated on marshalling blocks in pair order, making this very efficient and easy to maintain. This type of marshalling arrangement is suitable in several situations:

PLC, DCS, and ESD Marshalling Checks Inst Tools

One of the important interface function of the marshalling cabinet is the cross wiring function. Cross wiring is always necessary since the incoming field signal and the channel quantity of the I/O card is always different. For example let's say we have a 24 pair incoming field cable that carry 20 field analogue signal.