Food Grade Spray Paint Powder Coating Made In China Buy Paint Powder

Food grade powder coatings have several distinct advantages for food production: • They are able to withstand very hot and very cold temperatures. • Coatings make surfaces resistant to hot oils and fats, steam and water. • Powder coatings protect equipment involved in food preparation. Powder coatings help reduce downtime in food.

Orange Color Food Grade Powder Coating Recyclable Environmental Protection

I am fairly new to powder coating and am wondering if there are coatings that are food safe. B.C. Answer: Yes there are some powder formulations that are FDA (Food & Drug Administration) and NSF (National Sanitary Foundation) approved. In fact, they are used in the food industries every day.

FDA Food Grade Powder Coating for steel food container Buy FDA Powder

Food Grade Coatings. Since 1970, Endura ® has developed a wide array of FDA / USDA compliant coating systems for a multitude of food processing applications. We are specified and provide food grade coatings for a vast quantity of North American food manufacturer / processor and our coatings can be found throughout Europe & Asia in a number of our customers' subsidiary plants.

Food Grade Paint for Metal China Food Grade Powder Coating and Paint

The main characteristic of food-grade coatings is that can be eaten as part of the whole product, being particularly important in ready-to-eat fruits and vegetables.. Depending on the protein content, the powder is called whey protein concentrate (25-80%) or whey protein isolate, which contains >90% protein on a dry-weight basis .

What can be powder coated? Superior Powder Coating Utah Superior

Food Safe Metal Coating #3: Electropolishing Steel. Technically, this isn't a food grade coating for metal, but rather a type of finishing process for food safe steel. In many instances, rather than using a coating, food manufacturers will use uncoated metal that has been specially finished to enhance smoothness and resistance to corrosion.

Epoxy Polyester Food Grade Fire Retardant Antique Copper Powder Coating

The DECC Company is an applicator of FDA acceptable food grade coatings that add value to the food production industry. FDA acceptable release coatings allow for an easy to clean and durable surface. Many food ingredients are abrasive in nature. These ingredients can quickly wear away the surface finish of the part they come in contact with.

AUTOMTOIVE SOLUTIONS Ral Food Grade Coatings, Packaging Type Bottle

Some key benefits of food grade polyethylene powder coating for refrigerator shelves include: 1. Durability: The coating is designed to withstand regular wear and tear, as well as temperature fluctuations and chemicals commonly found in food and beverages. 2. Easy to clean: The smooth surface of the coated shelf makes it easy to wipe down.

Food Grade FDA Approved Powder Coating Paint, kingstonpowdercoating com

Decc's FDA Acceptable Coating System Options. At The DECC Company, we have narrowed our focus to three FDA acceptable coating application choices to ensure our customers can find a high quality and commercial grade solution to their specific coating challenge. Please contact us in regards to your FDA coating challenge.

Powder Coating Detailed Designs Auto Spa

Summary. Food grade coatings are a great way of fighting the risk of contamination and bacteria growth. If you do not have a food-safe coating you may want to think about having one installed, not only are you more likely to meet your food safety regulations or food hygiene rating, it also helps to make the cleaning process easier. Distribution.

Powder Coating Types by Great Dane Powder Coating 7245379709

Brian Benchoff. October 25, 2015. If you don't yet have a toaster oven you can't use with food, here's yet another reason: DIY powder coating. Powder coating is much harder and more durable.

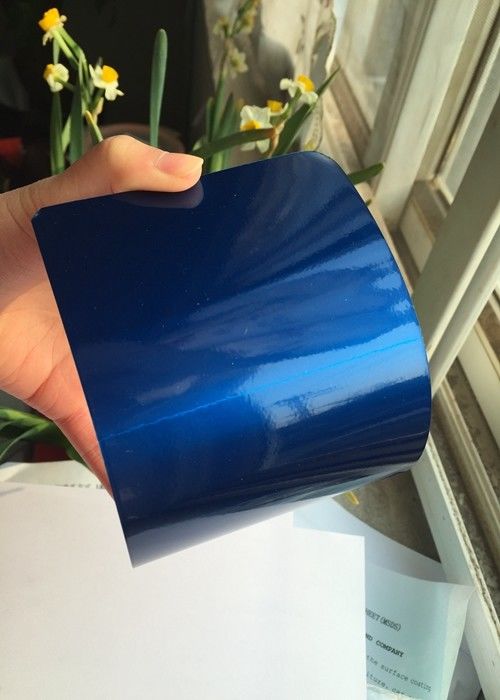

Oil Resistance Toy / Food Grade Powder Coating No Pollution RoHS Standard

Food packaging printing inks and coatings may be indirect food additives as they could have direct, indirect or incidental contact with food. 3. Barrier Coatings Stop Migration. FFDCA recognizes that a functional barrier can prevent a substance from migrating into and becoming a component of food.

Materials you can Powder Coat Powder Coating The Complete Guide

Abstract. The food packaging industries are facing the challenge of food waste generation. This can be addressed through the use of edible coating materials. These coatings aid in extending the shelf life of food products, reducing waste. The key components of these coatings include food-grade binding agents, solvents, and fillers.

Buy Germany imports Edible food gold color powder

These FDA approved, food grade powder coating products enhance surfaces to make them durable and long-lasting. These non-stick coatings for the baking industry and food preparation industry help food processing equipment function with exceptional efficiency as a result of these coatings' exceptional wear performance. The potential for food.

Rejuvenate Your Equipment With Powder Coating Amnor Powder Coating

The choice of food grade powder coating for a part will depend on the manufacturing process. Parts that will be placed in an oven will have to withstand high temperatures; parts that will be submerged in liquid must have a high resistance to corrosion. Non-stick coatings with a low friction coefficient are often sought in the food processing.

Buy Germany imports Edible powder Coating Green color

Food Safe Metal Coating #3: Electropolishing Steel. Technically, this isn't a food grade coating for metal, but rather a type of finishing process for food safe steel. In many instances, rather than using a coating, food manufacturers will use uncoated metal that has been specially finished to enhance smoothness and resistance to corrosion.

Food Grade Epoxy Coating Powder, Packaging Type Pp Bag, for Industrial

A powder coating is made up of several constituent substances which can all vary depending on the type of powder coating used. Powder coatings always use a resin, curing agent, additive, post additives, and tint pigments. Resins make up the bulk of the powder coating and are most commonly made of polyester, epoxy, or nylon.